Our Machinings

Our goal is Precision. Rapidity. Quality.

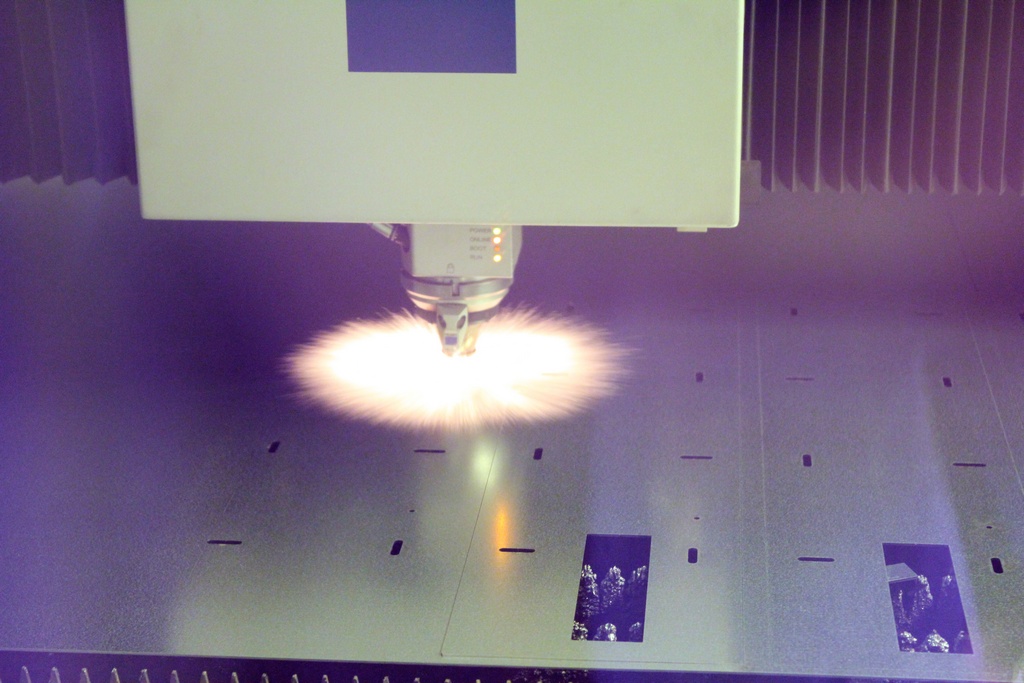

Laser cut

With our experience and technologies, we can handle cuts on small and large sheets, working with high precision on any type of track, following your exact specifications. Our 2D laser cutting service offers a professional, competitive and fast solution to cut a wide range of sheet materials, including Construction Steel, Galvanized and Stainless Steel, Brass, Aluminum, Copper and Titanium.

Our production process, regardless of the number of units required, allows us to process both large and small product productions, while maintaining high quality and precision even in the most elaborate and intricate cases. Upstream of the process we are also able to provide additional optimizations to our customers such as making design changes at the designing stage to meet any specific need.

We work with two Trumpf 2D laser cutting machines that can handle sheet metal up to 4mt in length and 2mt in width with thicknesses from 0.1mm up to 25mm. Equipped with C02 Laser and solid state FIBER Laser we can efficiently, competitively and accurately meet every request as quickly as possible.

All cutted materials can be delivered with complete certification and traceability, so we have the best quality cut on the best quality material.

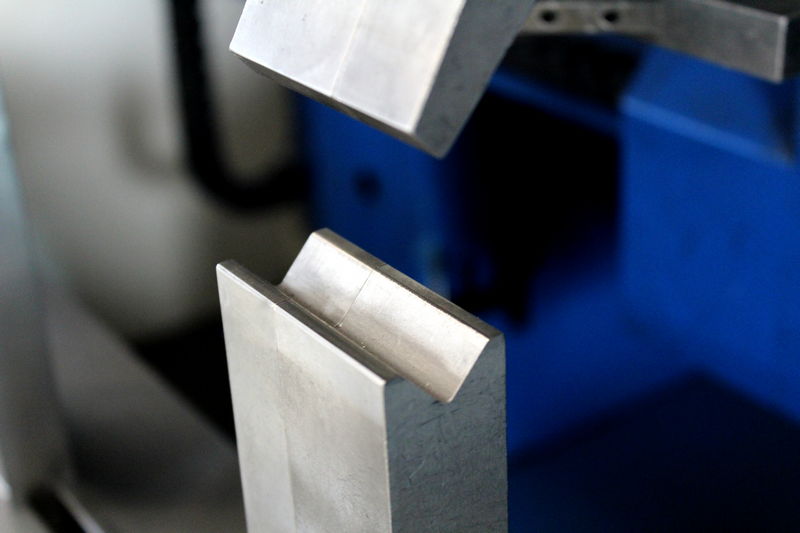

Bend and Calendering

With the combined power of a consolidated know-how and modern technologies we can follow the processing needs of small and big dimension products, and we are able to provide competitive, fast and high quality service.

By continuously updating our technical skills and tools we can improve our production methods to give a very high quality products at the lowest total cost. Thanks to the decennial know-how and the state-of-the-art technologies, we can meet the needed specifications of each of our customers, no matter the complexity of the project even in the most complicated cases.

We operate with 3 CNC benders capable of handling materials of thickness from 0.1mm up to 10mm with maximum dimensions of over 3mt. We also process product using a fully robotized bender and using a calendering station. These technologies make us capable to offer a complete and effective set-up of services.

Depending on the type of project, we handle the production process by choosing the most appropriate technology with the main goals of optimizing cost for the customers and meeting your specific needs, even on smaller and more precise products, always with high repeatability.

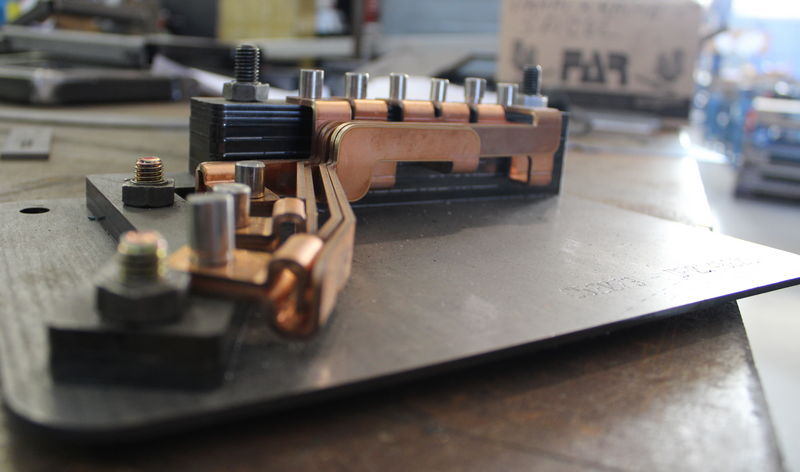

MIG - MAG - TIG Welding and Projection Welding

With the use of competitive technologies, we provide a high-quality welding service. Thanks to the combination of tools and our experience we can operate with many materials, including Iron, High Resistance Steel, Stainless Steel, Aluminum, Brass, and Copper.

By choosing a MIG-MAG-TIG welding in manual workstations, a MIG-MAG welding in Robotized workstations and a projection welding, we are always able to follow the direction of our customer's requirements, while maintaining the high quality and precision standards we offer, having the goal of a economically competitive, dynamic and timely production cycle.

Our Inverter welderswith Adaptive Control Points ensure a high quality of operation and allows us to work with materials such as aluminum, brass, and copper.

Assembly

With our dedicated assembly stations, we provide fast and accurate service. Using our technologies and our experience we aim to offer high flexibility to respond to each client's requests.

Having different welding, bending, and tooling technologies like metals belt saws and threading machines, we provide a service that is not limited by the size and the number of production of units. Our product flow management structure provides to customers the flexibility necessary to meet your needs, following the main goals of precision, economic competitiveness, and rapidity in the timings.

Metrology

To verify the high precision standards we adopt, we constantly make strict controls on our products. We use a dedicated workstation with a calibrated table and 3D measurement arm to check and control the tolerances throughout all the production flow, based on the requests of each customer.

It is important for us to provide a fast and cost-effective production service, without ignoring the precision: using certified measurement instruments we control all mathematics and dimensional tolerances to provide the possible best results to our clients.

services for finished products

For a complete Offer, our production flow manages additional external services for finished products such as paintings, zinc coatings and other surface treatments.

If our customers require it, we will develop and communicate appropriate solutions through our verification and research, always following the competitive, precision and fast standards that are imperative in our delivery policy of each order.