About Us

Our goal is Precision. Rapidity. Quality.

Our Company

For over 30 years we have been working in sheet metal processing, supplying parts and subassemblies for the automotive sector, industrial vehicles, process and agricultural machinery, handling systems, and much more. Our facility, with a plant of over 2,000 sqm, allows us to manage the entire production cycle with flexibility and efficiency.

Thanks to a dynamic and highly qualified team, advanced technology, and constant focus on quality, we continue to grow and provide our customers with reliable and competitive solutions.

Our strengths

Technological Innovation: we use state-of-the-art machinery and tools to ensure precision and quality.

Continuous Training: we believe that the value of a company lies in the skills of its team, which is why we constantly invest in professional growth.

Specialized Production: we guarantee reliable delivery times, responding quickly to market demands without compromising on the quality of the finished product.

Flexibility and Responsiveness: we guarantee reliable delivery times, responding quickly to market demands without compromising on the quality of the finished product.

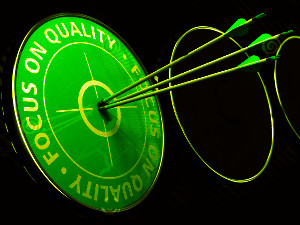

Quality and Certifications

We have been certified for over 10 years according to UNI EN ISO 9001:2015 and UNI EN ISO 14001:2015 standards, demonstrating our commitment to quality and environmental sustainability.

We have an advanced traceability system that allows us to monitor every stage of the production process, from order receipt to delivery. In addition, we adopt strict security measures to protect company data.

Order Management

Thanks to an integrated management system across all departments, we efficiently plan and develop production processes, adapting to the specific needs of each customer. We ensure compliance with quality and safety standards even for small batch production and prototypes.

Our technical department is available to support customers in the industrialization and optimization of product manufacturing strategies.

Technical Office

Our technical department uses CAD/CAM software to ensure precision and optimization at every stage of the manufacturing process. Thanks to dedicated workstations and advanced tools, we can visualize and refine projects before production, ensuring maximum efficiency and quality.

Logistics and Deliveries

To ensure fast delivery times, we have several automated warehouses with a wide range of raw materials always available.

We work with various national and international carriers, selected based on specific transport needs, ensuring fast shipping and optimized costs.

Thanks to our experience, innovation, and attention to detail, we offer our customers a complete, reliable, and competitive service.

Contact us to find out how we can support your business!

Our Story

-

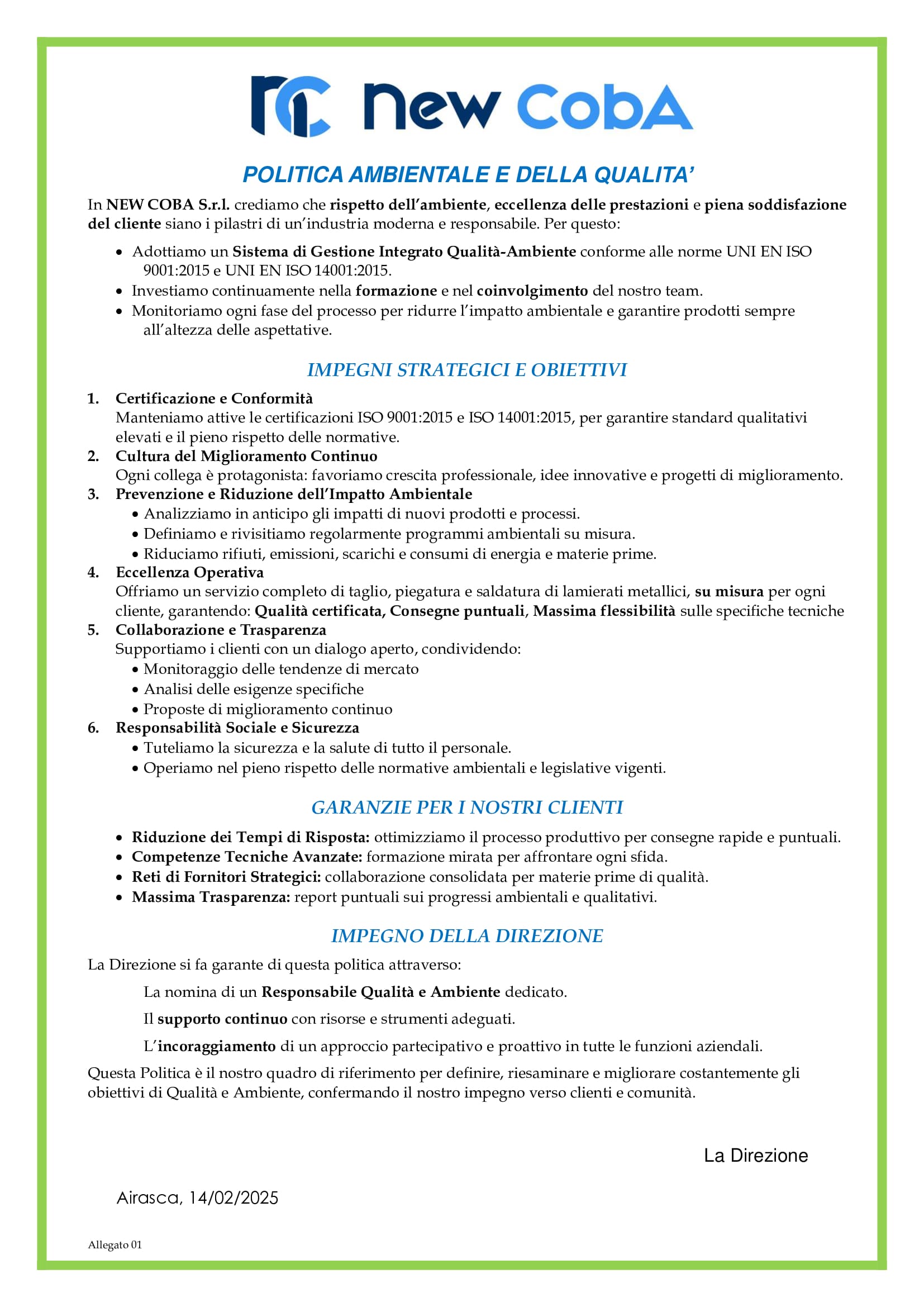

2025

Robotic Bending Cell – Large Format.

This new automated cell unlocks further possibilities for automation, competitiveness, and quality in the services offered by New Coba.Capable of handling parts up to 100 kg in weight, and combined with flexible software, it enables us to offer attractive production solutions to our customers. -

2024

The photovoltaic power plant for electricity production becomes operational.

The energy aspect is increasingly important both environmentally and economically. The combination of energy generation with a self-production system for technical gases used in laser cutting now makes New Coba more sustainable and independent. -

2021

New Coba expands its machinery fleet by introducing a semi-automatic panel bender. This allows the production of a new range of parts with speed and flexibility, overcoming some of the limitations of traditional manufacturing technologies.

From door frames to deep-drawn trays with high bending edges, it is now possible to create components for a wide variety of applications across diverse industrial sectors. -

2019

In a competitive landscape, New Coba invests in Innovation and Quality: an automated robotic press brake has been introduced, capable of completing production batches of different parts by automatically equipping itself.

Furthermore, to meet customers' quality requirements, an automatic grinding and satin-finishing machine has been installed to refine parts after cutting. -

2018

With the EN 1090-1:2009 + AI:2011 Certification, has been achieved the recognition for this execution classes:

- EXC3 for metal carpentry

- EXC4 for laser cutting for third parties

in the steel production use area, according to EN 1090-2.

Furthermore in the following year, the New-Coba will enter the new challenges of additive manufacturing technology through 3D Printing: it will be a year full of Innovations and Experimentations in the field of Additional Production. -

2017

New-Coba is on the market with three Qualitative and Productive Objectives; during the current year the following certifications were obtained:

- UNI EN ISO 14001:2004

- UNI EN ISO 9001:2015 Update -

2016

The second Laser Cutting Machine is purchased, introducing the Fiber Diode technology. This is also supported by a dedicated Automatic Warehouse that can operate in full autonomy. The Welding Technology is also updated with a new inverter projection welding machines, extending the company's operating range.

-

2007

A new Robotic Folding Press is introduced. Not yet a widespread technology, it is part of the management plan already in place: follow the continuous technological upgrading of production processes. In the same year, CO2 Laser Cutting is also introduced.

-

2005

After the introduction of robotic welding with the purchase of anthropomorphic welding robot, skills and competencies are rewarded not only by the production success but also by the achievement of the UNI EN ISO 9001: 2008 certification.

-

2000

Market scenarios is changing; The family decides to get away from the now too big company, not in an evolving process and weighed down by the bureaucratic structure. We decide to "puts back to the Center" the ability of the Individual. By buying a property in Airasca, the company's current venue, we continue with the aim of achieving a productive pole young and dynamic, getting ready to make a generational pass. Always focused on keeping the manual skills of men, we start to projecting towards the innovative investments that globalization imposes.

-

1992

The company, in order to face the challenges of the market, join a group, which altogether has more than 200 employees, leading in the construction of complete agricultural/earthmoving machinery cabins.

-

1983

Andrea Faragi, the father of current owners, founded Coba snc, a family-owned company specialized in revision, stamping and welding sheet metal.